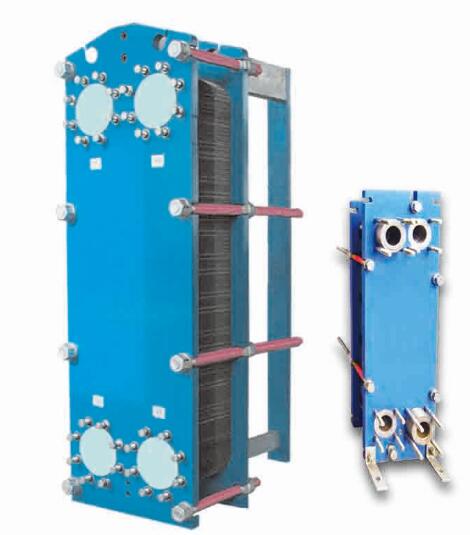

Brazed plate heat exchanger is a new type of high-efficiency heat exchanger formed by stacking and welding a series of corrugated metal plates in a vacuum brazing furnace. There are meshing contact points between the plates, and the fluid flows along the corrugated channels between the plates. Its velocity and direction change constantly, forming strong turbulence, which destroys the boundary layer and reduces the thermal resistance. Compared with the traditional shell and tube heat exchanger, its heat transfer coefficient is much higher under the same flow resistance or pump power consumption. Some data show that under working conditions, the water side heat transfer coefficient can reach about 6000 w / (M2 K), and under general working conditions, the water side heat transfer coefficient can also reach about 4000 w / (M2 K), which is 3 ~ 5 times that of shell and tube heat exchanger [1].

Each corrugated grid node of the brazed plate heat exchanger becomes a welding point, so the strength increases. Compared with the traditional removable plate heat exchanger, it not only eliminates the rubber pad easy to leak, but also greatly reduces the thickness of the heat transfer plate and the clamping plates at both ends, and reduces the heat transfer resistance. The price of the heat exchanger made of high quality stainless steel is only the price of shell and tube heat exchangers made of ordinary carbon steel with simultaneous interpreting heat transfer capability.

Due to the above characteristics, brazed plate heat exchanger has a general trend to replace the traditional shell and tube heat exchanger in some fields. Therefore, the heat transfer performance and flow resistance of plate heat exchanger were studied.

中文(简体)

中文(简体)